Coil winding was once considered as a tedious task. The reason for this is because, there were no specialized winding equipment available to support the winding operations. Instead, coil winding activities were done manually, which involved several issues like tangling, and in turn damaging the coil. In such circumstances, workers would require to put extra effort to untangle coil, which was a time consuming activity.

Coil Winding Heads Made Things Easier

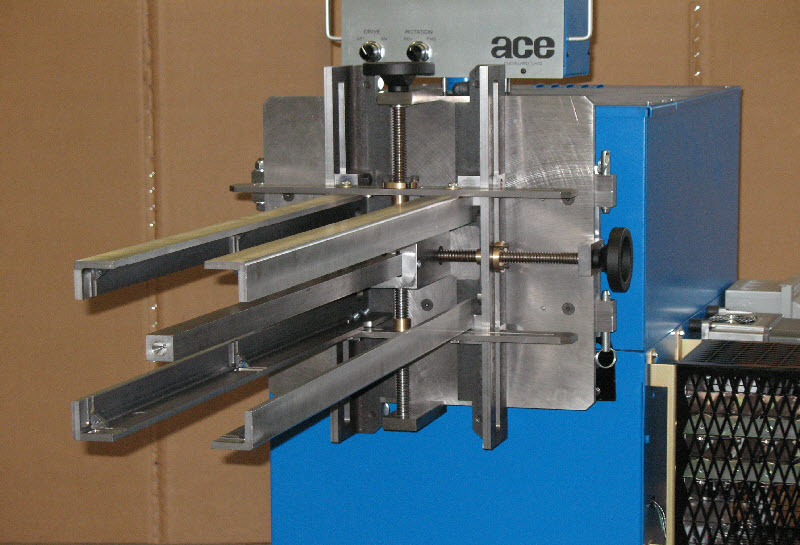

Yes, things are now easier than the past with the availability of coil winding heads. They are exclusively designed to easily and quickly produce mush coils that precisely fit for your applications. Winding heads are available with several numbers of slots and sizes to wind coils of varied dimensions.

Still not fully convinced with the capabilities of winding coil machine heads? We have lots more beneficial advantages to tell you about the product.

- Heavy duty construction to withstand harsh conditions in the application areas. They are comprehensively coated with high impact Nylon for superior corrosion protection and to resist wear and tear.

- Simple and compact design assuring easy setup, and simple operation.

- Offered with a holder featuring instant coil release mechanism. This assures easy coil removal just after winding.

- Rigid construction allows for quick and neat winding of coils.

- Rugged construction with two polished aluminum cones firmly attached to a cast iron base, assures years of unfailing service.

- The wounded coils require no taping – you would just need to tie the leads.

Today, single and group winding heads, which allow several identical coils to be wound at a time are available on the markets. These are popularly used in the coil winding industry due to their ease of use and ability to wind coils precisely. They are amongst the most cost-efficient equipment available supporting coil winding tasks of several industries.