Metal parts cleaning is not as straightforward as it seems. There are various challenges that can make the process of choosing a metal parts cleaning service difficult. Nonetheless, there are certain steps you can take in choosing the right parts cleaning service and equipment.

Factors Affecting the Selection Process

Before we delve into the actual selection process, there are certain points that must be considered. Successful metal parts cleaning depends a great deal on the following factors:

- Time: This refers to the amount of time taken to clean the parts.

- Mechanics: The actual process that is utilized to clean a metal part. Examples of mechanics would be heating, scrubbing, soaking, or spraying.

- Temperature: The adequate temperature required to effectively remove all coatings and contaminants from a part.

Also, it should be pointed out that the service provider can adjust these factors to ensure that a metal part is effectively cleaned.

Challenges when Selecting a Metal Parts Cleaning Service or Product

Considering the above factors, let’s look at the problems that are generally faced when choosing a metal parts cleaning service.

- Quality of Cleaning: Many industrial facilities utilize components in chemical processes. The components need to be rid of all chemicals before being reused. With various types of chemicals being used in many manufacturing processes, there is an increasing demand for minimal residual contamination once the cleaning process has been completed. Finding a metal parts cleaning provider who can meet this demand can be difficult.

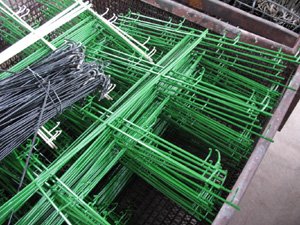

- Chemical Stripping: When it comes to metal parts cleaning, many service providers utilize caustic chemicals to clean parts like hooks, racks, etc. Chemical stripping is preferred by many, as it can remove rust, and allows for paint respraying, as well as custom paint jobs. However, it should be noted that chemical stripping can be quite hazardous. Exposure to the chemicals can lead to drowsiness, headaches, dizziness, and lack of body coordination. It can also result in ailments such as skin and eye irritation, and even terminal health conditions like cancer, brain, liver, or kidney damage, as well as reproductive problems. Chemical stripping is also expensive. Installation of chemical stripping machines itself costs around $18,000.

- Complex Parts: New technologies have resulted in new materials and innovative designs being used in manufacturing processes. Due to this, a variety of complex components are being created. The components are manufactured with various types of grooves, holes, ridges. This makes it tougher to perform the parts cleaning process effectively.

- Cleaning Performance: Taking the previous two points into consideration, the cleaning performance has to match up to customer demands. The cleaning process has to meet the requirements of customers, as well as safety and environmental regulations. As parts given for cleaning are provided in bulk, there has to be consistency in the cleaning performance. Also, the possibility of rework or additional cleaning steps should be eliminated.

- Cost-effectiveness: Quality and cost-effectiveness are two factors that customers always look for in parts cleaning services. The service provider needs to offer his services at a reasonable rate, while providing a high degree of quality. If a service provider charges to high an amount for a single cleaning process, then customers will obviously turn to someone else.

These are the challenges that are faced by customers when choosing a metal parts cleaning service. We will discuss the solutions for the same in the next post.